Our Capabilities

Timberline Capabilities

Our requirements-driven capabilities include mechanical and electromechanical engineering, electronics design, industrial design, design validation, prototyping and testing, supplier partnerships, and tooling and production startup. We are ready to assist you at any stage of your product’s development.

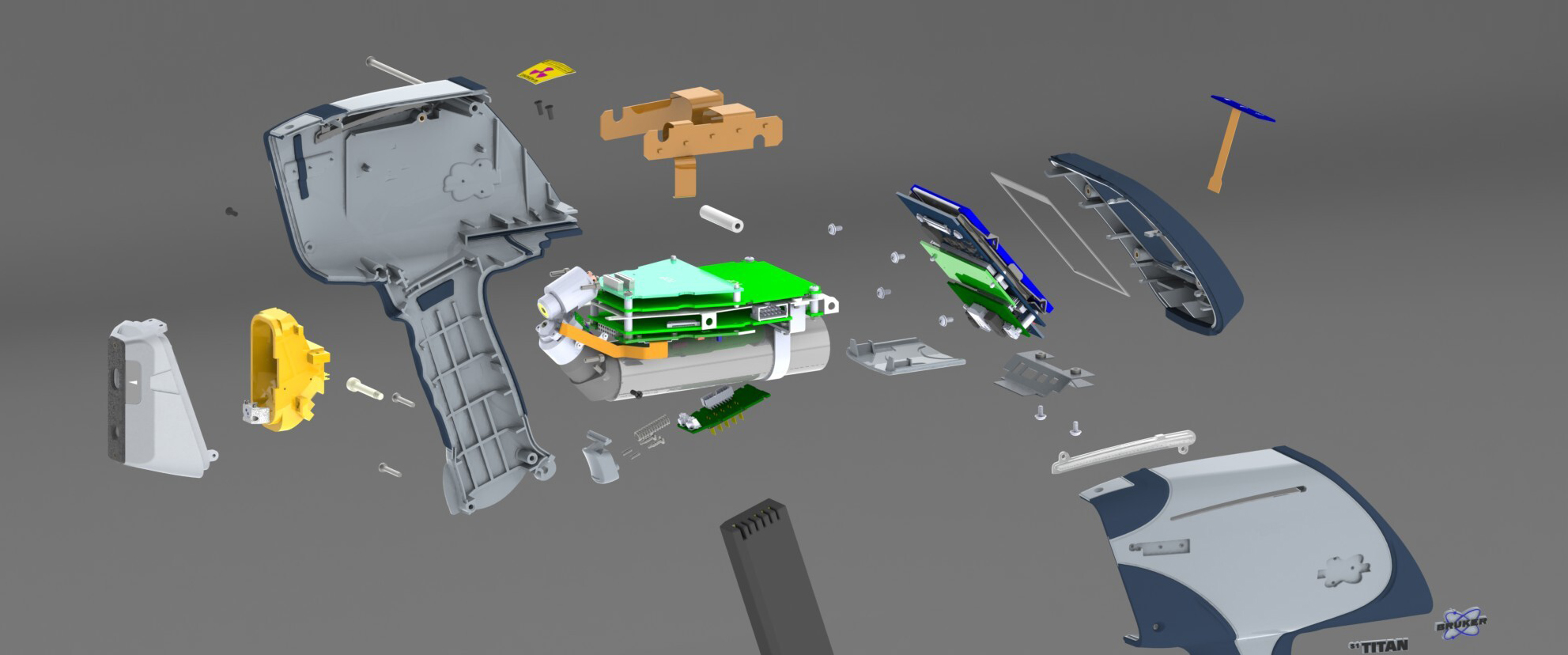

Mechanical and Electromechanical Engineering

Our mechanical and electromechanical engineering expertise includes everything you need to create exceptional, manufacture-ready products, from complex motion control and automation to injection mold design and materials selection. We can also design for machined components, weldments, and sheet metal.

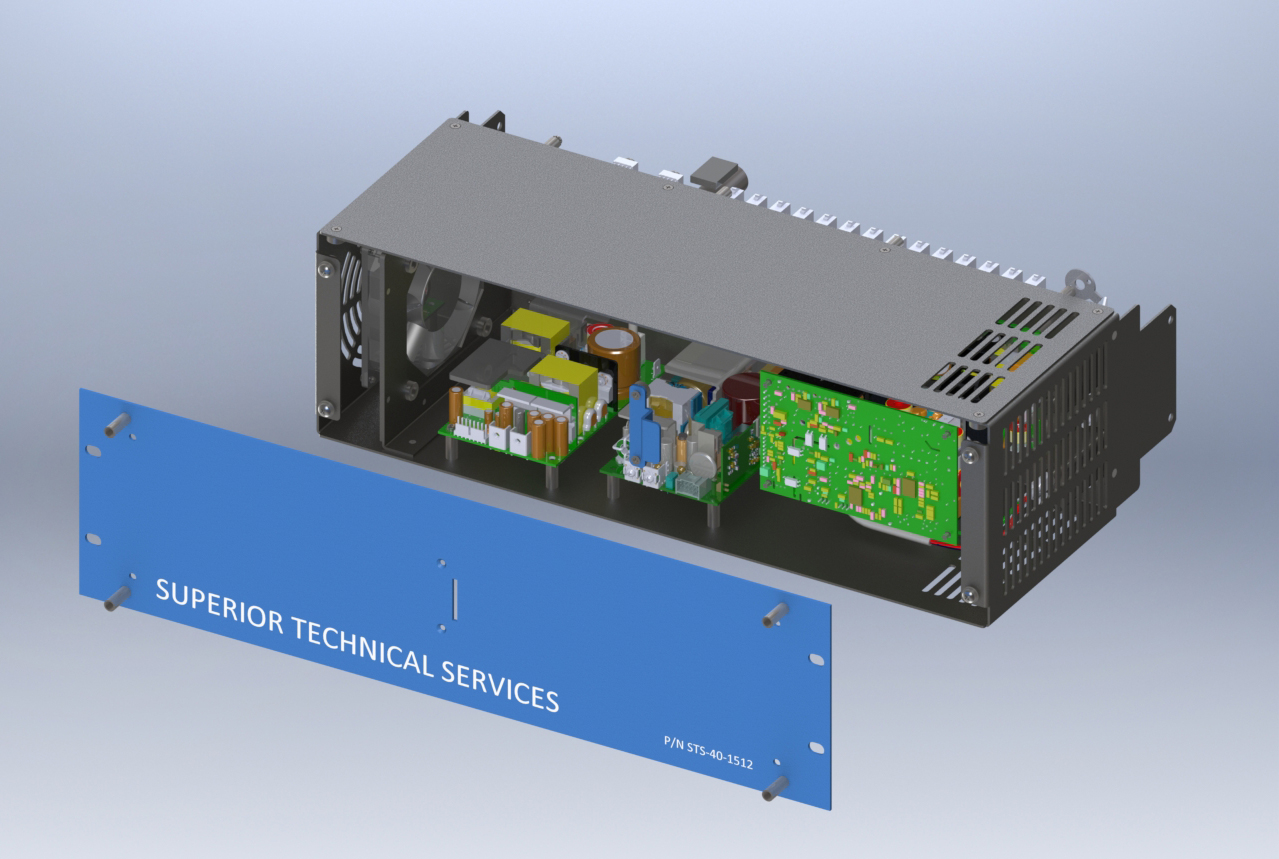

Design for Manufacturing

Ensuring products are prepared for successful manufacturing is crucial. One way we do this is by providing a wide range of design services including electronics design, advanced circuit and pcb design, and firmware development. Combined with our electromechanical capabilities, we make sure our clients end up with finished designs that perform well, are easy to manufacture and cost-effective to produce.

Industrial Design

Elegant products require elegant design solutions. This is why Timberline takes a deep look at your desired market and competitors to provide a holistic understanding of how your product will fit into the current marketplace and how you can differentiate your product in the minds of your customers. Our industrial design capabilities take into account functionality, ergonomics, and visual appeal as well as manufacturability.

Prototyping and Testing

Timberline’s in-house prototyping capabilities provide fast and efficient prototyping that lets you prove out design concepts quickly and stay on track for your important product development milestones. Our prototyping services include 3D printing, prototype tooling, machining, and even prototype pcbs for electronics.

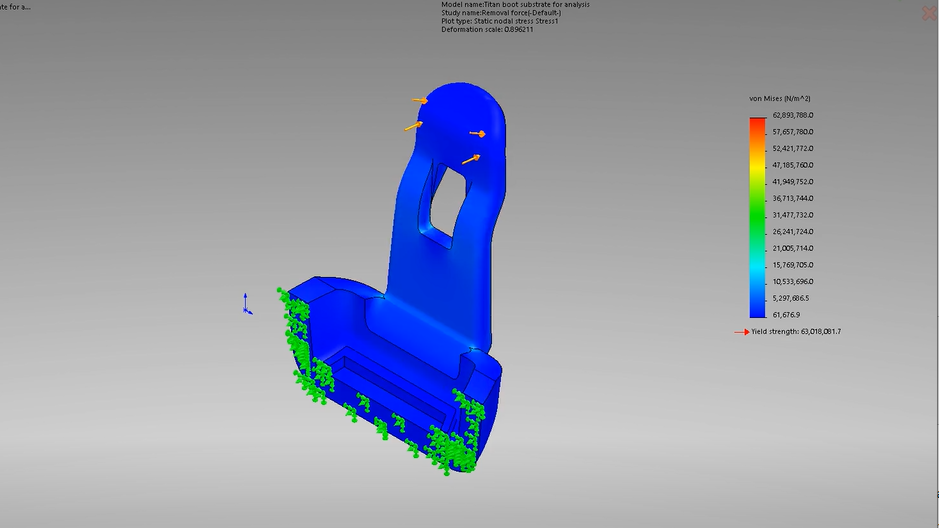

Design Validation and Testing

Many of Timberline’s clients begin their relationship with us by taking advantage of our in-depth design validation and testing capabilities to verify the durability and functionality of their products. Our design validation capabilities include structural analysis and FEA, thermal analysis, and other product simulations. We can also help you meet requirements for functional testing, HALT testing, and other regulatory requirements as needed.

Supplier Partnerships

At Timberline, we are proud to maintain a robust partner network that includes all of the resources you need to bring your products to market successfully. We can connect you to a wide range of industry experts, whether you require assistance with metals manufacturing, PCB / SMT assembly, injection molding, software development, or even app development. We manage all of the scheduling, communication, and planning so you aren’t stuck managing multiple partners.

Tooling and Production Startup

One of the things that truly sets Timberline apart from other design firms is our ability to create a seamless transition for products as they move into production. Our team of experts can assist with vendor selection and qualification, engineering support, and validation testing during tooling development.